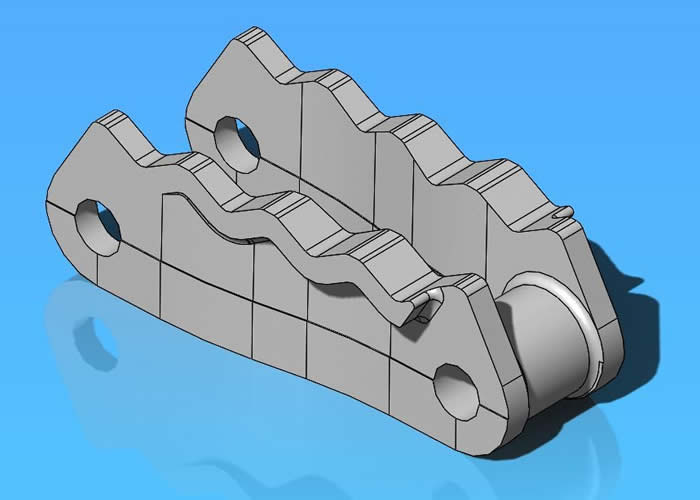

Technology is changing at a rapid pace. As it does, the parts necessary to drive technological change become ever more intricate. Omega can render our customer’s part in a 3D environment and test that part using sophisticated finite element analysis to determine where the strength is needed and where it is not.

As a result, with minor changes, the part can be strengthened and possibly lightened to create efficiencies in our customer’s processes.

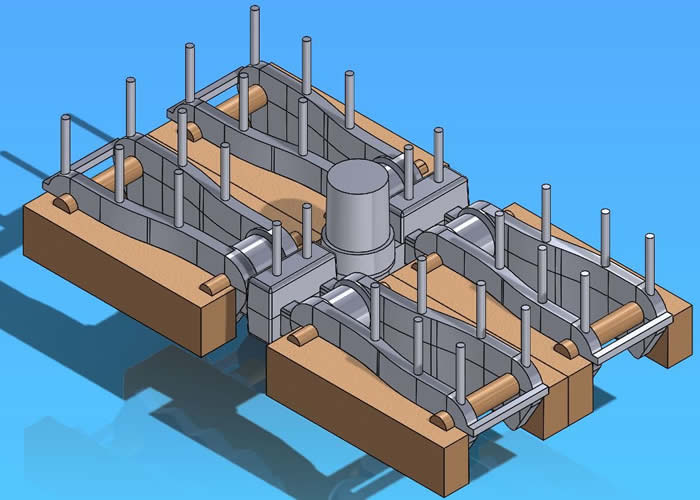

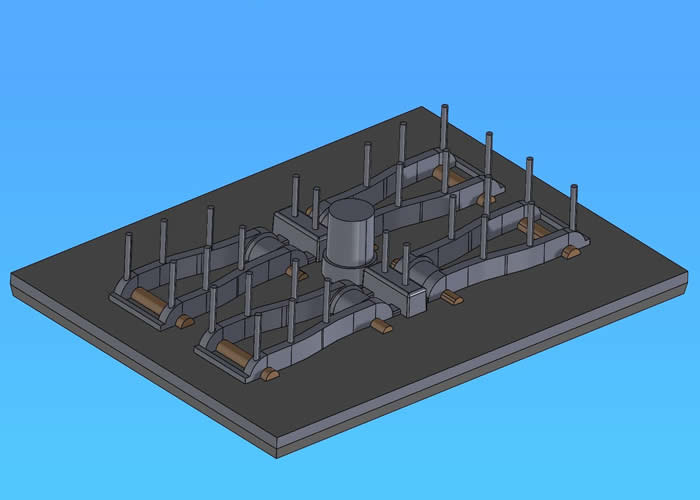

In addition to designing the part, Omega has the knowledge and capabilities to develop the patterns needed to produce our customer’s part. This service includes designing the rigging, gating, and riser placement to produce parts without defects as efficiently as possible.

This is done through 3D rendering of the part in its cast state. After adding the necessary components, the casting of the pattern is simulated using top of the line software. This begins with the simulation of the pour and finishes with a solidification simulation of the casting.

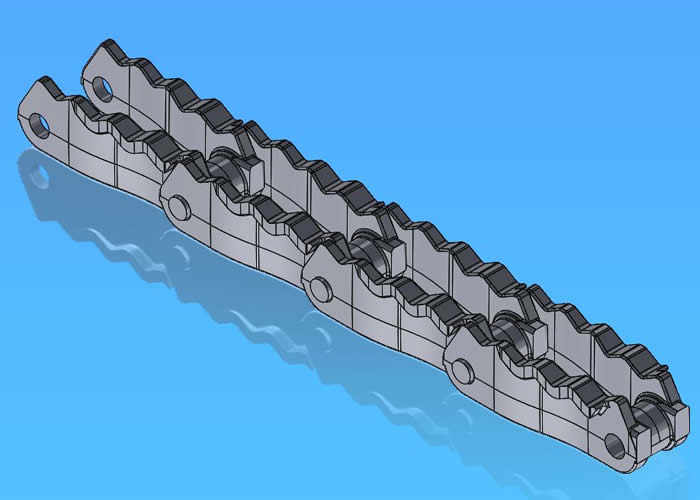

As Cast

As Cast With Rigging

With Rigging

Drag Pattern

Drag Pattern

In the ever-more-competitive global marketplace having a furnace operating at top efficiency is not only important, it is essential. For this reason Omega has developed and pioneered the synchronized drive technology that allows for more furnace load capacity while at the same time increases the life of the belt used. We are more than happy to diagnose our customers' furnaces to see if synchronized technology is right for them. If so, we will do all the calculations free of charge.

Furnaces break down for many reasons. Sometimes these reasons are not obvious so Omega Castings maintains a failure analysis laboratory to determine root causes of furnace belt and drive mechanism failures. This service is also provided free of charge to our customers.

Also offered by Omega is the ability to repair (when possible) existing equipment and return it to the customer quickly so they are up and running with minimal downtime. Common repairs made are replacing pins in belts and trunnions in broken roller assemblies. This service can be a very cost effective option when the rest of the belt or roller assembly has a fair amount of life remaining.

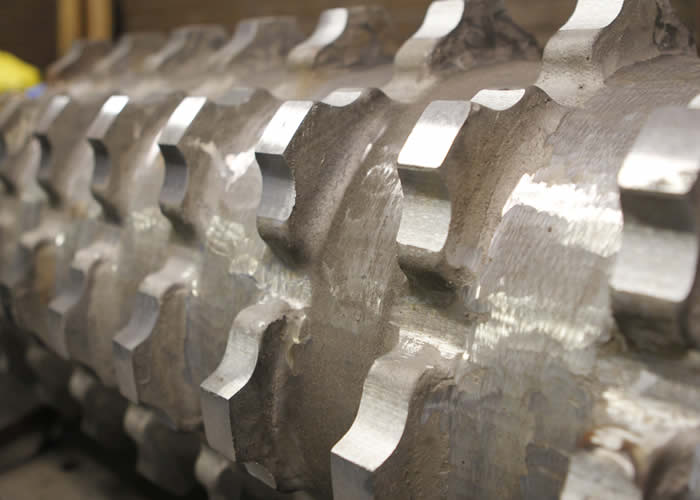

Reprofiled Drive Drum

Reprofiled Drive Drum

Contact Us with your specific needs. We will give you a free consultation and provide the best service in the industry.

In 1975, Omega Casting's founding mission was to produce alloy castings and assemblies with superior metallurgical and dimensional integrity and to deliver those castings and assemblies in a timely manner to our customers at a competitive cost. (READ MORE)

In the ever-more-competitive global marketplace having a furnace operating at top efficiency is not only important, it is essential. For this reason Omega has developed and pioneered the synchronized drive technology that allows for more furnace load capacity... (READ MORE)

After running several companies, Robert Cutshall founded Omega Castings, Inc. in 1975. It was during a gas shortage and Battle Creek, Michigan was picked as a location due to its natural gas reserves. Locating in Battle Creek assured that there would be fuel to run... (READ MORE)